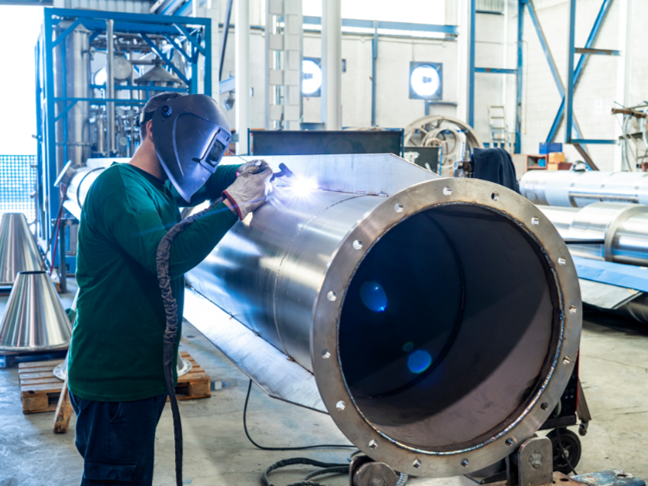

Materials

Wide Ranging Selection of Alloys

At EMS Fabrication, we custom fabricate a wide variety of materials to meet your needs, including various alloys of steel, stainless steel, super-stainless chloride resistant alloys, aluminum, copper, and more.

Steel

We fabricate high-quality cold rolled and hot rolled steel products.

Hot Rolled Steel:

- Features a rough, textured finish

- Easily fabricated into a wide range of shapes and configurations

Cold Rolled Steel:

- Boasts a smooth, polished finish

- Offers superior strength compared to hot rolled steel

- Well-suited for applications requiring precise dimensions and a sleek appearance

We also fabricate a variety of additional steel alloys to meet your specific needs and requirements.

Stainless Steel

Stainless steel is an exceptional material for fabrication, known for its excellent resistance to corrosion and rust. Its surface does not need to be painted and has a clean, sleek look. Following are common stainless steel alloys that we fabricate.

304 Stainless Steel:

- Widely used in various applications due to its excellent corrosion resistance and formability.

- Commonly found in appliances, architectural components, and automotive parts.

316 Stainless Steel:

- Offering enhanced corrosion resistance compared to 304 stainless steel, 316 is particularly well-suited for resistance to chlorides and applications involving harsh chemicals.

- Often used in medical implants, food processing equipment, evaporators, water treatment, and marine environments.

400 Stainless Steel:

- While the 400 series of stainless steel provides less corrosion-resistance than 300 series alloys, it has very high strength and is magnetic.

- This grade is known for its high strength and wear resistance, making it ideal for applications that demand mechanical durability.

- Commonly found in cutlery, fasteners, automotive exhaust components, and industrial components.

We also fabricate a variety of additional stainless steel alloys to meet your specific needs and requirements.

Super-Stainless Steel

Superaustenitic stainless steels are typically utilized when greater resistance to corrosion is required, especially for protection from chloride pitting and crevice corrosion. Following are common super-stainless alloys that we fabricate.

AL-6XN:

- High PRE (pitting resistance equivalent) alloy used in demanding high temperature environments where resistance to a wide range of corrosive substances, including acids, chloride solutions, and seawater, is required.

- Commonly utilized in chemical processing, pulp and paper production, heat exchangers, marine applications, and more.

Alloy 254:

- Another excellent chloride-resistant alloy, similar to AL-6XN

- The most commonly used superaustenitic stainless steel alloy.

Aluminum

Aluminum is a low cost light weight material. It weighs significantly less than steel and stainless steel. It has good strength but not as strong as stainless steel. The most common types of aluminum we fabricate include:

5052:

- Popular alloy within the 5xxx series of aluminum alloys which are known for their excellent corrosion resistance and moderate strength.

- Commonly utilized to manufacture automotive parts, kitchen appliances, fuel tanks, signage, and boats.

6061:

- Precipitation-hardened aluminium alloy that has good mechanical properties, exhibits good weldability, and is commonly extruded.

- 6061 T6 is one of the most commonly used versions. "T6" refers to the temper or degree of hardness. With great formability and weldability, it is used for engineering and structural applications, boats, furniture, and more.

Other Common Alloys

EMS Fabrication also has extensive experience with the following alloys.

- Duplex and super-duplex alloys

- Hastelloy (C-276, C-22)

- Titanium

- Inconel (600, 625, 718, more)

- Copper

- Brass

- Bronze

- And more...