Sheet Metal Assemblies

Specializing in Complex Fabricated Assemblies

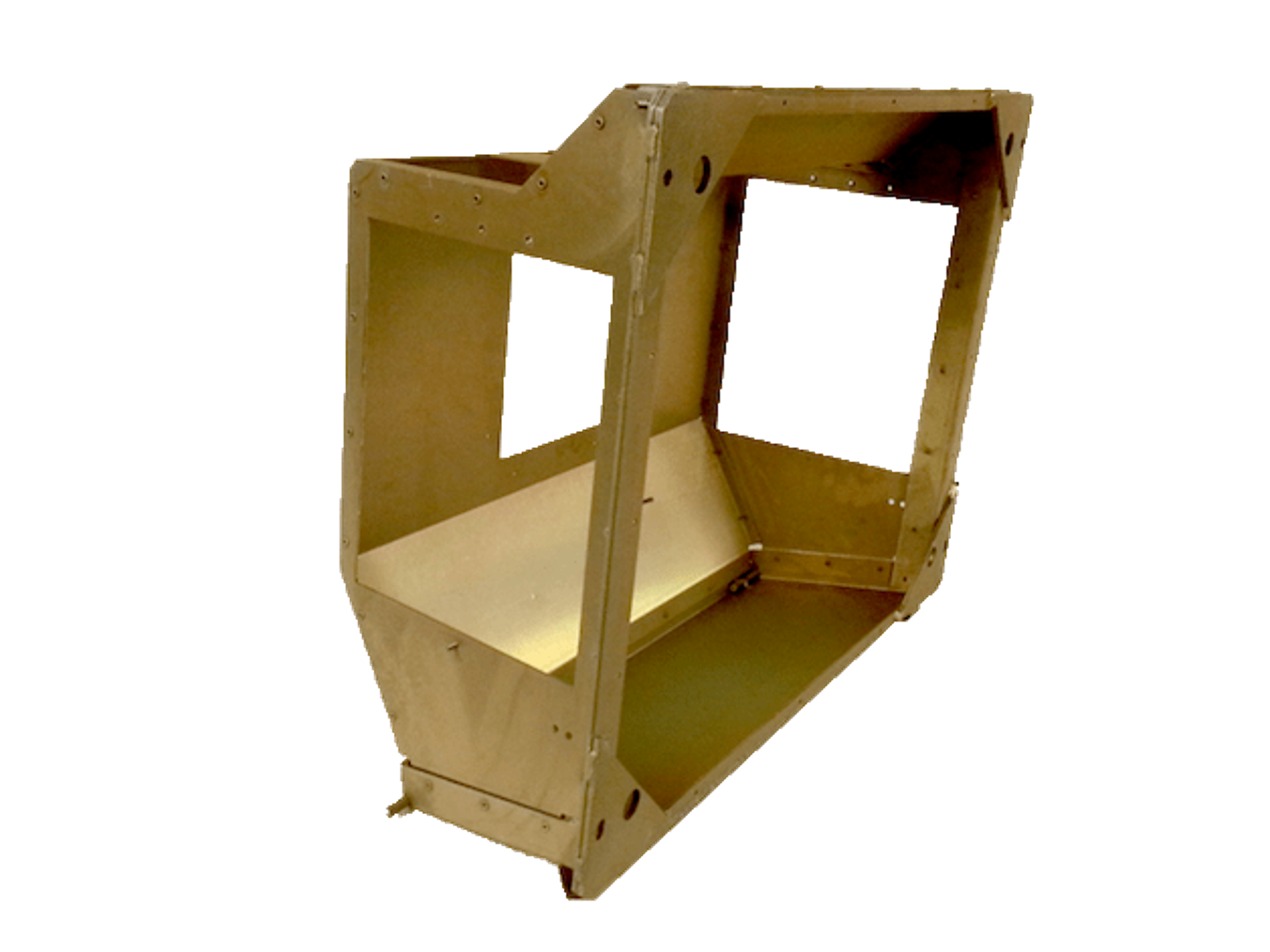

At EMS Fabrication, we specialize in fabricating complex assemblies including intricate chassis, enclosures, and more, to meet your needs.

Sheet Metal Assembly Services

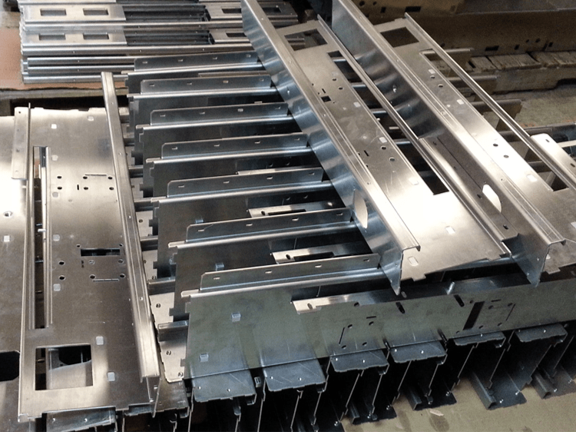

Sheet metal assembly involves joining multiple sheet metal parts together to form a complex or complete structure. These services are crucial in various industries including automotive, aerospace, electronics, and construction, as they allow for the creation of intricate components and structures from flat sheets of metal.

- Joining: The shaped pieces are assembled and joined together using various methods such as welding (TIG, MIG, Spot Welding), riveting, or bolting.

- Hardware Installation: Hardware such as screws, nuts, bolts, rivets, and PEM fasteners are installed to further secure the assembled parts and provide additional functionality.

- Finishing: After assembly, the product may go through various finishing processes to enhance its appearance, durability, and performance.

- Quality Control: Assembled products undergo quality control checks to ensure they meet the required specifications and standards.

Common Types of Sheet Metal Assemblies

- Structural Assemblies: Used in creating frames, supports, and other structural components.

- Functional Assemblies: Assemblies that play a crucial role in the functionality of a device or machinery, such as enclosures, brackets, chassis, and housings.

- Aesthetic Assemblies: Components that are visible in the final product and require a high level of finish and precision.

- Integrated Assemblies: Combining sheet metal parts with other components like PCBs, cables, or plastic parts to create a complete assembly.